什么是线束?

2025.12.26

2025.12.26

行业新闻

行业新闻

线束是电气和电子系统的基础组件。以下是详细解析:

核心定义

线束(通常也称为线缆组件或电线束)是一种预组装的集成系统,由电线、电缆、连接器和保护套管组成,用于在大型设备内部或多个设备之间传输信号和电力。

可以将其视为复杂设备的中枢神经系统或血管系统。它将分散的电线整合为一个有组织、安全且易于管理的成套组件。

关键组成部分

典型的线束包括:

-

电线/电缆:用于传输电力和信号的导体。

-

端子:压接在电线末端的金属接头,用于实现电气接触。

-

连接器(壳体):固定端子、确保牢固插合并提供防错插(防止错误插入)的塑料或金属外壳。

-

保护套管:导管、编织层、螺旋缠绕管或波纹管,用于捆扎电线并保护其免受磨损、高温、潮湿和化学物质的影响。

-

应力消除结构:在连接器处固定线缆的特征设计,防止拉力损坏电气连接。

-

胶带、扎带和卡箍:用于内部捆扎并将线束固定在设备框架或底盘上。

主要功能与目的

-

组织性:用单一、整齐的组件取代混乱的分散电线。

-

简化安装:作为一个整体进行“即插即用”式安装,极大减少了组装时间和复杂性。

-

保护性:保护电线免受环境危害和物理损伤(如振动、磨损)。

-

安全性:容纳并绝缘电线,降低短路、电气火灾和干扰风险。

-

可靠性与质量控制:在受控环境中按照精确规格制造,确保持续稳定的性能。

-

可维护性:设计便于连接/断开,使维护和部件更换更加容易。

应用领域

线束广泛应用于所有涉及电气系统的行业:

-

汽车行业:应用广。一辆现代汽车的主线束可能包含超过1500个连接器和5公里长的电线,连接从发动机ECU到尾灯和信息娱乐系统的所有部件。

-

航空航天:必须能承受极端条件、可靠性要求极高且重量极轻的线束。

-

消费电子:用于家电、电脑、电视和游戏机内部。

-

工业机械:用于工业机器人、数控机床和控制面板。

-

医疗设备:用于成像系统(MRI、CT扫描仪)、患者监护仪和手术工具。

-

电信:用于服务器机柜、网络设备和基站。

设计与制造流程

-

原理图与布局:电气工程师创建原理图。线束设计师据此进行2D/3D布局设计,优化布线路径、长度和弯曲半径。

-

原型制作:制作物理样品,测试其适配性、形状和功能。

-

切割与剥皮:将电线切割至精确长度,并剥去端部绝缘层。

-

端接:将端子压接或焊接在电线末端。

-

插入:将端子插入连接器外壳。

-

组装与捆扎:在线束组装板(全尺寸模板)上组装电线,并用套管、扎带和胶带捆扎。

-

测试:电气测试至关重要。进行导通性、短路、电阻测试,有时还包括耐压(介质耐受)测试。

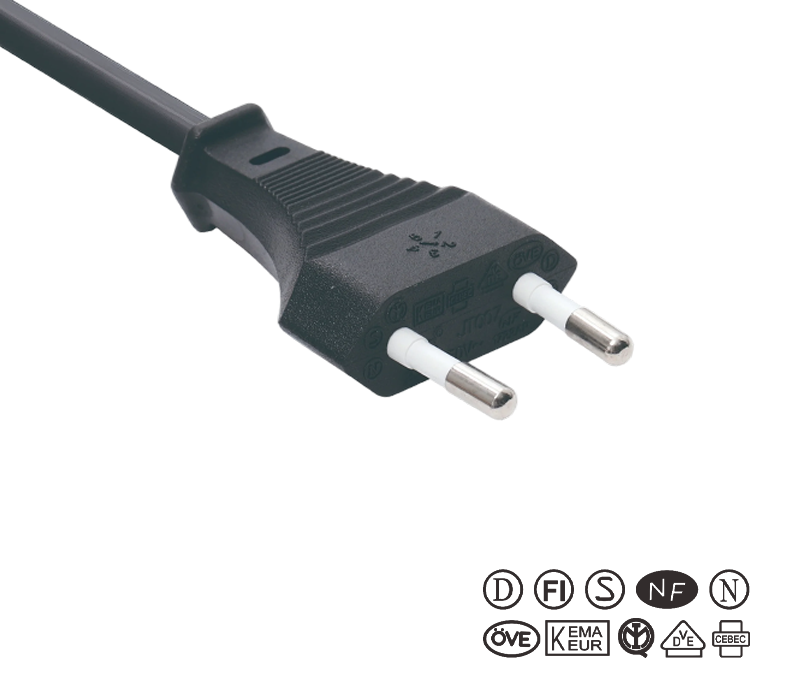

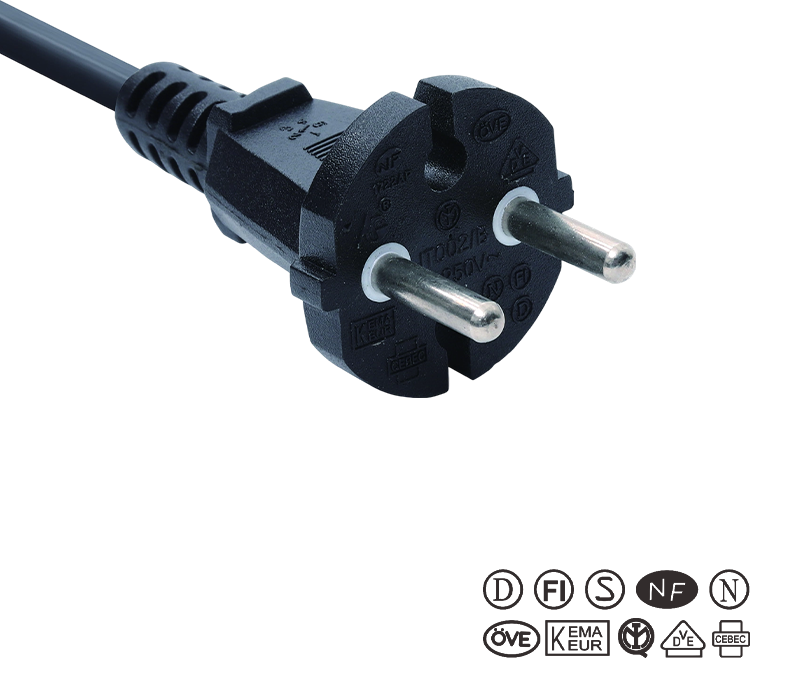

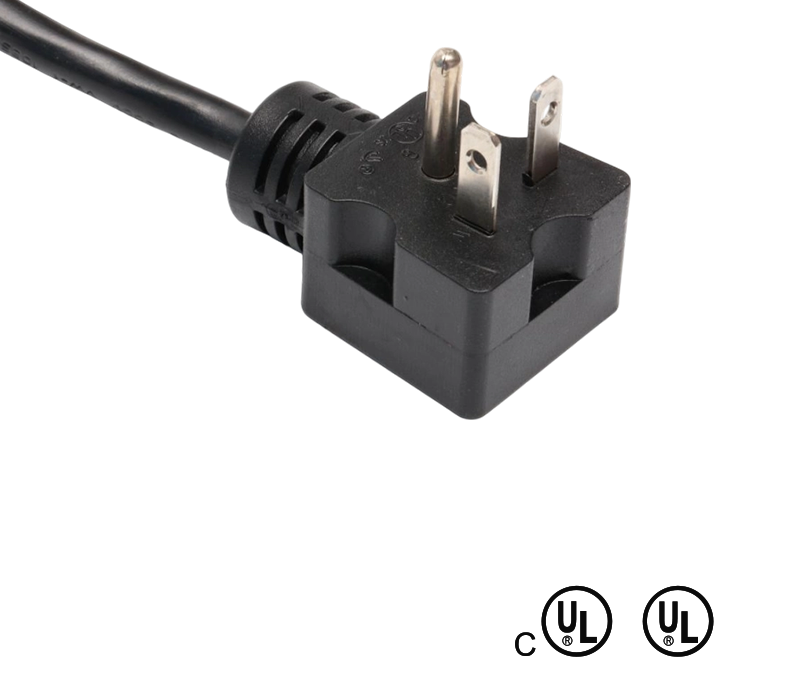

线束 vs. 电缆组件:有何区别?

这是一个常见的混淆点。

-

线束:具有多个分支和不同的端点。它包含许多连接器,并在多个位置终止(例如,一个主干分出多路,分别连接前照灯、传感器和保险丝盒)。

-

电缆组件:通常是单一线缆,两端各有一个连接器。其目的是连接两个特定组件(例如,连接电脑和打印机的USB数据线,或电源线)。

简单类比:线束就像一棵有许多分支的树。电缆组件就像连接两个点的单根树枝。

总结

本质上,线束是一种定制化设计的集成布线系统,它为在复杂的电气/电子产品中可靠、安全、高效地分配电力和数据提供了一套方法。 它是一个关键组件,填补了电气设计与物理安装之间的空白。

English

English  Español

Español

手机:13586690829

手机:13586690829

浙江省宁波市余姚市泗北工业区

浙江省宁波市余姚市泗北工业区